The durability and seamless functioning of construction equipment, such as crushers, are greatly dependent on the availability of spare parts. Parts for Metso crusher, such as jaw plates, toggle plates and bearings, are crucial parts that keep the equipment operating well. To minimise downtime and increase productivity, routine examination and prompt replacement of these components are essential. Operators may reduce wear and tear, increase machine longevity and attain consistent performance in a range of crushing applications by investing in authentic Metso crusher parts and adhering to manufacturer maintenance recommendations.

Similar to this, parts for Terex crusher are essential to preserving the dependability and effectiveness of these devices. Over time, wear and tear can affect the performance and output of the crusher due to components including liners, blow bars and hydraulic parts. Operators should regularly check and replace any damaged Terex crusher parts to guarantee optimal performance. By using authentic Terex spare parts, you can prevent expensive repairs and early failures while also ensuring compatibility and performance. Operators may reduce risks and increase the return on investment in their Terex crushers by following a proactive maintenance strategy.

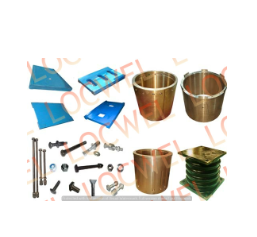

For crushing operations to continue operating at maximum efficiency and productivity, parts for Sandvik crusher are just as important as crushers themselves. Every part of the plant, from eccentric bushes and spider bushes to concaves and mantles, is essential to the crushing process. Frequent maintenance procedures, like lubrication, alignment checks and component inspections, are crucial for spotting possible problems and guaranteeing that Sandvik crusher parts are operating correctly. Operators may minimize downtime, optimize crusher performance and save overall operating costs by working with reliable suppliers and using authentic Sandvik spare parts.

Moreover, part for Schwing concrete pump are essential to preserving the effectiveness and dependability of concrete pumping operations. During pumping operations, parts such as delivery cylinders, wear plates and seals are subjected to high levels of stress and abrasion. Operators should follow a tight maintenance schedule to extend the life of Schwing concrete pump parts and avoid unplanned breakdowns. Critical components should be regularly cleaned, greased and inspected to assist spot wear or damage early on and for prompt replacement and repair. Operators may minimize disturbances on the job site and guarantee the flawless operation of their Schwing concrete pumps by investing in high-quality spare parts and adopting proactive maintenance methods.

Furthermore, routine maintenance entails taking proactive steps to stop problems before they start in addition to just replacing worn-out equipment. Regular lubrication of moving components is an essential component of preventive maintenance. A smooth operation, less wear and friction and efficient heat dissipation are all made possible by proper lubrication, which also increases the longevity of important parts. In order to guarantee optimum performance and keep impurities out of delicate engine or hydraulic systems, operators need also routinely check and clean filters, such as oil and air filters. Operators may improve the overall dependability and efficiency of their construction equipment by adding these preventative maintenance procedures to their regular schedule and reducing the likelihood of unplanned malfunctions and expensive repairs.

In order to guarantee that maintenance staff members have the abilities and know-how to carry out maintenance duties efficiently, operators should also place a high priority on their education and training. Offering thorough training on equipment operation, maintenance techniques and safety standards enables maintenance staff to recognize any problems early on, troubleshoot difficulties effectively, and carry out repairs accurately. Maintaining up to date knowledge of the most recent developments in construction machinery technology and maintenance procedures also helps maintenance crews to adjust to changing industry standards and best practices, which improves the equipment's performance and dependability even more.

Operators can use technology to expedite maintenance procedures and enhance equipment performance in addition to taking preventative maintenance actions. Telematics systems that deliver real-time data on equipment health, utilisation and performance indicators are offered by many manufacturers of contemporary construction machines. Operators can remotely check on the health of their equipment, anticipate future maintenance requirements, and plan maintenance chores by utilising telematics. Additionally, by analysing equipment data, predictive maintenance algorithms can identify possible issues before they happen, allowing operators to take preventive measures and save downtime. A competitive edge and cost savings are eventually achieved by adopting digital tools and technologies, which also improve maintenance efficiency and maximize equipment uptime and productivity.

In Delhi, Locwel is distinguished as a top provider and dealer of a wide variety of filters and spare parts for construction equipment. Focusing on quality, dependability and client pleasure, they provide a large assortment of crusher parts from leading manufacturers such as Metso, Terex and Sandvik in addition to parts for Schwing concrete pumps. Their vast product selection includes everything from lubricants and filters to worn parts and hydraulic components, guaranteeing that construction companies have access to the necessary materials to keep their equipment operating efficiently. The business also sets itself apart with its dedication to individualized service and technical know-how, offering clients professional advice on the best parts to use and maintenance strategies to extend the life and performance of their equipment. Construction companies in Delhi may relax knowing that their machinery maintenance needs are in competent hands when they work with Locwel, a dependable partner.